6 Asphalt Paving Scams Of The Season!

Does your driveway need an update? Well, with summer here, asphalt paving season is upon us! And with it come the inevitable scams that try to take advantage of unsuspecting property owners. So, are you dreading the thought of dealing with shady contractors? Don’t worry; we’ve got you covered! This blog post lists common asphalt paving scams; you must watch out for! Stay alert for the following excuses.

1) The Low Ball Estimate

This is when a contractor gives you an estimate much lower than the competition. They may even say they can do the job for half the price! Be wary; this could indicate that they will cut corners on the quality of materials and artistry.

2) The Pushy Salesman

We’ve all had that salesperson who’s just a little too pushy. With asphalt paving scams, the salesperson may pressure you into signing a contract on the spot. Or, they might say that the price is only reasonable if you act now. Don’t let yourself be pressured into anything you’re not comfortable with.

3) The Out-of-Town Contractor

Some contractors will leverage their position by saying they’re from out of town. They may say they can get materials at a discount because they buy in bulk. Or, they might say that they don’t have to charge sales tax. Be wary of any contractor who doesn’t have a local address or phone number.

4) Leftover Asphalt Scam

This is a common scam, where the contractor tells you they have leftover asphalt from a previous job. They’ll offer to pave your driveway at a reduced rate because they won’t have to pay for new materials. However, these leftover materials are often of poor quality and won’t last as long as fresh asphalt.

5) Watery Sealcoats

Some unscrupulous contractors will try to pass off watered-down seal coats as the real thing. The inferior product won’t protect your driveway as well as a quality seal coat; you’ll need to replace it more often.

6) Overlays

An asphalt overlay is a process in which a new layer of asphalt is laid over an existing one. This can be a legitimate way to repair damage or improve the appearance of your driveway. However, some contractors will try to sell you an overlay when you only need a seal coat.

There are always a few scam artists looking to take advantage of unsuspecting homeowners. Stay alert for unlicensed and uninsured contractors and out-of-the-blue paving experts asking for hefty upfront compensation. However, with Bay Country Contractors, you can feel confident that you’ll get desirable returns on your pavement investment. We offer reliable full-service asphalt maintenance and site development services in Stafford. Get a free estimate for your pavement project today.

One of the most significant aspects of home ownership is maintaining your property. This includes regular upkeep and bigger projects like remodeling or making additions. If you’re thinking about paving your driveway or patio, you must do your research first and avoid making common mistakes. In this blog post, Bay Country Contractors will outline the most common mistakes when specifying paving requirements and how to avoid them.

Specifying Paving Needs: The Importance!

Paving a driveway or patio is a significant investment. Not only do you want it to look good, but you also want it to last. That’s why getting the specs right the first time is essential. But what exactly does that entail? Let’s outline everything you need to know about specifying paving, from material selection to thickness.

1. Overlooking the Importance of a Good Base

The most typical mistake people make when specifying paving is overlooking the importance of a good base. The base provides stability and support for the paving stones, so it must be made of high-quality materials.

There are two main bases: granular (e.g., crushed stone) and cementitious (e.g., concrete). Granular bases are typically cheaper and easier to install, but they’re not as durable as cementitious bases. Cementitious bases are more expensive and difficult to install, but they’re much more durable and will last longer.

So, which one should you choose? It depends on your budget and how long you want the pavement to last. A granular base may be the way to go if you’re on a tight budget. But a cementitious floor is better if you want your pavement to last for many years.

2. Not Compacting the Base

Once you’ve chosen the type of base you want to use, it’s important to compact it properly. If you don’t, the pavement will likely settle and crack over time.

There are two main ways to compact a base: with a plate compactor or with a roller. Plate compactors are smaller and less expensive, but they’re not as effective as rollers. Rollers are bigger and more expensive, but they do a better job of compacting the base.

Which one should you choose? Again, it depends on your budget and how long you want the pavement to last. A plate compactor may be sufficient if you’re on a tight budget. But a roller is better if you want your pavement to last for many years.

3. Choosing the Wrong Paving Material

Many paving materials are available on the market, including concrete, asphalt, brick, and stone. Each type of material has its advantages and disadvantages. For example, concrete is very durable but can be challenging to repair if it cracks. Asphalt is less expensive than concrete, but it doesn’t last as long.

When choosing a paving material, you need to consider your budget, the climate where you live, and how much traffic the pavement will get. If you’re unsure which type of material is best for your needs, consult a paving professional. They’ll be able to help you select the suitable material and give you an estimate of the cost.

Once you’ve selected a paving material, it’s time to start thinking about the design. If you’re not an experienced pavement designer, it’s easy to make mistakes that can cost you a lot of money.

Here’s How Bay Country Contractors Can Help!

Bay Country Contractors serving Ashburn, VA, offers Commercial Asphalt & Concrete Maintenance & Repairs. We can help you select the suitable material for your needs and budget, and we have the experience and expertise to install it properly. We also offer maintenance and repair services to keep your pavement looking its best.

If you need help with paving, get a free estimate from Bay Country Contractors today!

Stormwater Management: Why Is It Important?

Where does the rainwater go when it rains? Many people do not consider this subject until it is too late. The matter is that stormwater management is essential for keeping our communities and environment healthy.

Bay Country Contractors will discuss stormwater management and its importance in this blog post. We’ll also explain how to keep your neighborhood safe from stormwater damage.

What is stormwater management?

According to the Environmental Protection Agency in the US, stormwater management attempts to limit the water runoff from precipitation or melted snow into roadways, lawns, and other locations while improving water quality.

Stormwater is filtered into the soil and eventually fills aquifers or runs into streams and rivers. When heavy rains fall, the saturated earth produces extra moisture, which rushes across the surface and into storm sewers and road ditches. This water frequently transports trash, chemicals, bacteria, eroded soil, and other contaminants into streams, rivers, lakes, or wetlands.

Importance of stormwater management:

Reduce water pollution:

Soil works as a natural filter for precipitation, providing relatively pure water to rivers and groundwater sources. This process is absent in metropolitan areas, where rainwater travels across hard surfaces before entering storm drains. In this situation, water brings waste, chemicals, pathogens, silt, and other contaminants straight into streams, rivers, lakes, and wetlands. As a result, collecting runoff and removing toxins before releasing them into local waterways is one of the stormwater management goals.

Stop storm and sanitary sewage system overflow:

Stormwater facilities of various sorts are meant to store excess rainwater, but careful capacity estimations are required to avoid overflow. The same is true with sanitary sewer systems. Stormwater runoff does not travel through a treatment plant on its route to nearby waterways. Still, the sewer system itself may overflow if suitable stormwater management systems are not constructed and maintained.

Reduce floods and erosion:

When water falls on impervious surfaces, it flows quickly rather than slowly, soaking into the land. If not handled appropriately, this can result in floods, erosion, and infrastructure damage. Runoff may be managed and regulated with the proper stormwater infrastructure, averting devastating floods and decreasing soil erosion.

Keep the natural hydrologic cycle:

Stormwater management is important for sustaining healthy streams, lakes, and aquatic life and supporting human usage by preserving the natural hydrologic cycle.

Without effective stormwater management, infiltration can lower soil replenishment and groundwater recharge. It is worth emphasizing that soil moisture is necessary for plant survival, which is why it plays a part in maintaining the natural hydrologic cycle.

Comply with federal environmental laws:

Stormwater monitoring and control are becoming increasingly important as federal water quality rules become more strict. Businesses should prioritize stormwater management if only to avoid fines and penalties.

At Bay Country Contractors, we offer industry-leading stormwater management services to business owners in Stafford, VA. Our experts will check your property’s storm plumbing and retention system to determine necessary repairs, and we will then give an estimate for those repairs.

If you live in a place prone to sinkholes, you must know what they are and what to do if one forms near your home or business. Sinkholes can occur suddenly, and without warning, so it is essential to be prepared.

Bay Country Contractors will discuss sinkholes’ formation, effects, and repair. We will also provide tips to protect your property from sinkholes.

Sinkhole Formation and Effects

Sinkholes are formed when water erodes the rock or soil beneath the ground’s surface. This formation can take days, weeks, or even years. When enough material has been eroded, the floor above it will collapse, forming a sinkhole. Sinkholes can range in size from a few feet to several acres. Depending on the material that has been eroded, sinkholes can develop gradually or suddenly.

The effects of sinkholes can be devastating. They can damage homes, businesses, roads, and other infrastructure. In some cases, they can cause injuries or even death if people or animals fall into them.

Sinkholes can also disrupt water supplies and change the landscape dramatically. Sinkholes can also create environmental problems by draining groundwater and polluting aquifers. So, it’s critical to protect your property from sinkholes.

Signs of Sinkhole Formation

It is necessary to be aware of the signs of sinkhole formation. These include cracks in walls or floors, doors or windows that won’t close properly and sudden changes in groundwater level. If you suspect sinkhole formation, it’s essential to contact a professional sinkhole repair company as soon as possible.

While sinkholes can be dangerous and destructive, they are also a part of nature. With proper awareness and preparation, we can minimize the damage they cause and keep our communities safe.

Detecting Sinkholes

Report it to authorities or municipalities immediately if you see cracked, waterlogged, and depressed land or pavement. There is a high probability the region could be depressing by unstable soil, a ruptured utility, or a possible subterranean collapse. With proper precautions and quick action, we can minimize the damage caused by these high-risk natural phenomena.

Repairing Sinkholes

Repairing a sinkhole is a complex and expensive process. It often requires heavy machinery to remove debris and stabilize the surrounding area. In some cases, the entire affected site must be excavated and replaced with new material.

There are several ways to repair sinkholes. One method is to fill the hole with soil or concrete. It is often used for small sinkholes. Engineers may build walls around the hole’s edge for larger sinkholes to stabilize it.

In some cases, sinkholes can be filled with grout, a type of concrete that is injected into the ground. Of course, all this requires the sinkholes to be stabilized with required aggregates.

Ending Note

Sinkholes can form anywhere and anytime, so everyone needs to know them. If you suspect a sinkhole, Bay Country Contractors, serving Charlotte Hall, MD, can help you take the essential measures to protect your property from sinkholes.

We offer free estimates for our services, so please contact us today if you have any questions or concerns about sinkholes in your area.

Thanks for reading!

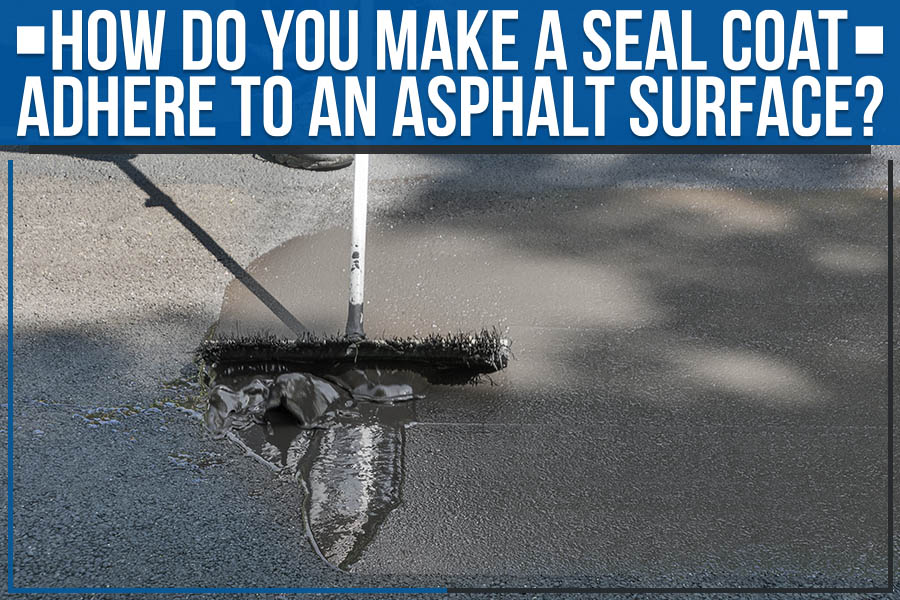

Sealcoating is an essential part of asphalt maintenance, as it helps protect the surface from weather and wear. But how do you make a seal coat adhere to an asphalt surface? It can be a challenge, as the seal coat needs to stick without bubbling or cracking.

You should take a few steps to increase the likelihood of a good seal coat-asphalt surface bond. Stay with us as we learn how to make an asphalt driveway seal coat stick.

Clean Surface is Essential:

One of the essential things you can do to ensure a good bond is to start with a clean surface. Any dirt, grease, or other contaminants will prevent the seal coat from adhering correctly. Cleaning the surface can be done with a power washer or a stiff brush.

You’ll also want to make sure the surface is dry before you begin applying the seal coat. If there’s any moisture present, it will evaporate and cause bubbles in the seal coat.

The Right Temperature is Essential:

The asphalt surface should be warm enough that the seal coat can flow easily but not so hot that it starts to melt. If it’s too cold, the seal coat will be challenging to apply evenly. You want the surface to be between 60 and 80 degrees Fahrenheit before applying the seal coat.

You can ensure this temperature by waiting for a warm, sunny day. If it’s still not warm enough, you can use a heater to raise the temperature of the asphalt surface.

Repair Surface Damages:

Alligator cracks, potholes, and other surface damages can cause the seal coat to fail. Before you start applying the seal coat, make sure to repair any surface damages. If the damage is too severe, you may need to replace the asphalt before you can apply the seal coat.

Repairing these damages may include:

- Patching

- Filling in potholes

- Repairing cracks with a sealant

Prime the Oil Spots:

Oil spots can also cause the seal coat to fail. You need to prime the oil spots before applying the seal coat to prevent this.

You can do this by:

- Scrubbing the oil spot with a degreaser

- Covering the oil spot with a primer

Once you’ve carried out these steps, you can start applying the seal coat. Make sure to do it in a well-ventilated area and follow the instructions on the product’s label.

What Factors Cause Poor Bonding?

Several factors may cause a poor bond between the seal coat and asphalt surface, including:

Rust Spots: Surfaces that are seal-coated without prior special treatment of rust spots may cause the seal coat to fail. The rust will come through the seal coat as silver streaks.

Polished Aggregate: Roughness is necessary for a good bond. If the surface is too smooth, it may need to be sanded before applying the seal coat.

Tree Sap: A sugary substance secreted by trees, the sap can act as a barrier between the seal coat and asphalt. The seal coat may fail in these areas unless the fluid is removed before application.

Conclusion:

Bay Country Contractors, serving Oxen Hill, MD, are experts in asphalt repair and maintenance. Contact us today for a free estimate for all your commercial asphalt and concrete repair needs.

Every property owner hates it when the asphalt they laid with so much love and consideration loses its glory. That once shiny asphalt parking lot is now faded, dreary, and possibly cracked in more places than you can imagine, and it will eventually start turning off your customers!

This is where sealcoating comes in. Not only is this protective layering method a cheaper alternative to laying your asphalt anew, but it also saves you precious time and resources.

Keep reading to learn about the various benefits of sealcoating your asphalt lot.

5 Benefits of Sealcoating Your Asphalt Parking Lot

1. It Saves You Money!

Sealcoating your asphalt will save you a lot of money over time. This protective layer will protect your asphalt lot from long-term damages, which could result in costly repairs and renovations.

2. Makes Your Pavement Look Good as New!

No matter the kind of sealer you have picked, the process of sealcoating leaves your asphalt looking almost as good as new. You will cherish the brand-new feeling emanating from your pavement as if you just laid brand new asphalt.

3. Protects Against Wear and Tear

Sealcoating will safeguard your pavement from the elements – including UV rays, oil spills, etc. – and thus wear and tear. Whether you drive a heavy vehicle like a truck or a compact convertible, your asphalt lot will likely undergo some depletion. However, a sealer may help slow down the process of asphalt erosion over time.

4. Boost Your Pavement’s Life Span

Due to its protective qualities, sealcoating will extend the life span of your asphalt parking lot. The process is no different from saving it from depletion, which contributes to prolonging the life expectancy of your pavement.

5. Protects Against Water Penetration

Water is asphalt’s worst enemy. If it seeps into your parking lot surface, it will eventually start destroying your pavement from within due to the freeze-thaw cycle. Sealcoating protects your asphalt from water penetration.

Some Important Considerations

Before you schedule sealcoating for your pavement, you need to remember the following:

- Depending on your asphalt layering, the type of sealer may vary. These can range from acrylic sealers, coal tar sealers, asphalt emulsion sealers, and more.

- Site prep is essential before sealcoating. If dirt or debris is covering your parking lot, it will prevent the sealcoat from adhering to the pavement.

- Make sure to check the weather. Sealcoating should only be done on warm days and needs at least 24 hours to dry. So, make sure there is no rain expected!

As you can see, there are numerous benefits to sealcoating your asphalt parking lot regularly. It not only saves you money and time, but it also enhances the life expectancy and appearance of your asphalt lot.

To cater to your sealcoating needs, Bay Country Contractors serving Brandywine, MD, bring their years of experience and team of experts to the table. Let us take care of all your asphalt needs (and more) today!

Air-Entrained Concrete 101: A Basic Guide

There’s a reason air-entrained concrete is specified so often for construction projects – it has a lot of advantages over traditional, non-air-entrained concrete. In this blog, Bay Country Contractors will discuss all this particular type of concrete, including some benefits of air-entrained concrete.

What is Air-Entrained Concrete?

Air-entrained concrete contains tiny air bubbles. These air bubbles serve as “stress relievers” and help increase the concrete’s durability. The entrained air makes the concrete more workable, so contractors like to use it in construction projects.

How is Air-Entrained Concrete Made?

Air-entrainment is the process of adding tiny air bubbles to concrete. The process involves adding an air-entraining agent to the concrete mix. The volume of entrained air will depend on the type of air-entraining agent used and the amount added. There are different pressure and volumetric methods to test the amount of air content in the concrete mixture before pouring.

Applications of Air-Entrained Concrete.

Air-entrained concrete is commonly used in sidewalk and driveway construction. Air-entrained concrete is often used in dams, bridges, tunnels, and road construction. This type of concrete can be called reinforced concrete and has the same uses as standard concrete. Its best application is in areas with freezing conditions, like can be seen in the state of Virginia, USA.

Uses of Air-Entrained Concrete.

Air-entrained concrete has many benefits that make it desirable for construction projects.

1. Resistance to Freezing/Thaw Cycle – One of the most significant advantages is that it is less likely to crack in freezing temperatures. In negative temperatures, concrete can deteriorate faster than intended. The air bubbles in the concrete act as tiny freeze-thaw chambers, increasing the concrete’s resistance to the freeze/thaw cycle.

2. Increased Workability and Finishing Quality – The entrained air also makes this type of concrete more workable, which leads to a better finish. The workability of concrete refers to it being easier to manipulate, place, and compact.

3. Increased Durability – This type of concrete is more durable owing to the fact that it is more resistant to freezing temperatures and is easier to work with.

4. Water Resistant – It should be no surprise that air-entrained concrete is more resistant to water. The air bubbles increase the porosity of the concrete, which helps it resist water intrusion.

5. Reduced Bleeding – Bleeding is the process in which water rises to the surface of the concrete. The bleeding water can lead to a weaker finished product. By entrapping air in the concrete, bleeding lessens.

6. Increased Resistance to Chemicals – Air entrained concrete is also more resistant to chemicals. The increased porosity helps to protect the concrete from damage by chemicals.

7. Lightweight and Economical – Air entrained concrete is also lighter weight than traditional concrete. The lightweight concrete can be an advantage in some construction projects. It is also more economical due to the reduced amount of material needed.

Bay Country Contractors are experts in providing concrete paving, repair, and maintenance services in the Fredericksburg, VA area. Contact us with your queries or get a free estimate!

Concrete is a sturdy, reliable building material. But just like any other material, it can benefit from reinforcement when used in areas that will see a lot of wear and tear. When it comes to concrete reinforcement, there are two main options: rebar and mesh. Both have their benefits and drawbacks. So, should you use rebar or mesh to reinforce your concrete? Here’s what you need to know.

What is Rebar?

A rebar is a steel bar used to reinforce concrete. It is commonly used in driveways, parking lots, and sidewalks. Rebar comes in different sizes and lengths.

What is Wire Mesh?

Wire mesh is also made from steel, but it is a mesh of wires welded together. This material is often found in driveways.

Rebar v Mesh: Which is better for Lots and Driveways?

The answer depends on what type of construction project you’re undertaking. But here are some factors that you must consider before deciding which option to go for:

Cost:

Wire mesh is a cheaper steel reinforcing material than rebar. It uses thin steel wires while rebar is a steel bar, and the cost depends on its thickness and size. Rebar may also cost you more in labor. The high cost of rebar may not be justified if it’s a private driveway or a small area or if you are on a budget. However, it might be cost-effective when used in commercial settings.

Installation:

Wire mesh is easier to install than rebar. So, if your project is time-sensitive, then wire mesh may be the best option. It even requires fewer workers to install as compared to rebar.

Flexural Strength:

While both types are strong, rebar has better bend strength properties than wire mesh and provides better support to the concrete for high or heavy traffic. Rebar is a good choice for projects that will experience a lot of wear and tear, such as industrial lots, underground parking lots, or other commercial parking lots. Wire mesh is a better option for light to medium traffic areas like driveways and sidewalks.

Transport:

If your project site is located far from the supplier or transportation is tricky, wire mesh is a better option as it weighs significantly less than rebar. The lightweight mesh will save on transport costs. Nonetheless, both can withstand the rough conditions during transport.

Thermal Expansion:

Steel and concrete have similar expansion properties when it comes to temperature changes. As a result, wire mesh and rebar will expand and contract at the same rate as concrete. Therefore, concrete bound to these steel reinforcements cracks at a lesser pace than it would without any support.

Structure Type:

Wire mesh is suitable only for horizontal slabs like driveways, patios, and sidewalks. On the other hand, contractors use rebar for horizontal and vertical applications such as walls and columns.

Corrosion Resistance:

Rebar is more corrosion-resistant than wire mesh and can last up to 100 years if properly coated and maintained. Wire mesh will erode much faster; however, various treatments can be applied to protect the wire mesh from rust.

Discuss the suitability of rebar and mesh with your concrete contractor, specific to your project type.

Bay Country Contractors provides high-quality reinforced concrete paving services to its commercial clients in Manassas, VA. Contact us for your next concrete project or get a free estimate for any of our concrete and asphalt services!

How To Prevent Your House From Flooding

Flooding can be a significant problem for homeowners, widespread flooding. In some cases, flooding is simply unavoidable. But in many instances, there are things that homeowners can do to prevent their houses from flooding.

Bay Country Contractors will discuss tips and tricks for preventing your house from flooding. We will also discuss what to do if your home does flood.

Ways to Prevent Flooding

1. Keep the Gutters Clean

One way to prevent flooding is to ensure that your gutters and downspouts are clean and in good working condition. If your gutters have any obstruction, they will not be able to drain water away from your house properly. It can cause water to build up around your foundation, eventually leading to flooding. Therefore, it is essential to clean your gutters and downspouts regularly and repair them if they are damaged.

2. Grade the Ground Around Foundation

Another way to prevent flooding is to grade the ground around your foundation to slope away from the house. It will allow water to flow away from your foundation. You should also make sure that there is no vegetation growing too close to your foundation, as this can hold moisture against the foundation and eventually lead to flooding.

3. Prepare a Plan to Deal with Emergency

If you live in an area exposed to flooding, you can do a few things to prepare for it. First, you should have a plan for what to do if your house does flood. It includes having a list of emergency numbers, knowing where your important documents are stored, and planning how you will evacuate your family and pets. You should also purchase flood insurance, which will help cover the cost of damages if your house does flood.

These tips can help prevent your house from flooding. However, even if you take all of the necessary precautions, there is always a chance that floods can occur. Suppose you get in a situation where your house is flooding; make sure to stay safe. Do not try to enter the floodwaters, as they can be very dangerous. Instead, call 911 and wait for help to arrive. These measures can help keep your family safe from floods.

Ending Note

No one wants to face a flood, but it is essential to be prepared if it does happen. Bay Country Contractors would like to remind our readers that we are here to help in the event of a flood. We have a lot of experience dealing with these types of emergencies and want to ensure that our clients recover from a flood as soon as possible. If you live in the Alexandria, VA, area and are worried about flooding, please consult us for more information or assistance preparing for a potential flood.

When most people think about construction projects, the first things that come to mind are concrete and steel. But what they don’t realize is that without proper soil stabilization, those projects could quickly crumble.

In this Bay Country Contractors blog post, we’ll talk about soil stabilization and how it helps your construction project set the proper foundation. There are three methods for soil stabilization: compaction, drainage, and reinforcement. Which one will work best for your project? Keep reading to find out!

Methods for Soil Stabilization:

Soil stabilization is a process that is often overlooked but can be highly beneficial for construction and erosion control projects. There are many different methods of soil stabilization, including compaction, drainage, and reinforcement, each with its benefits and drawbacks.

Compaction:

Compaction is often used in construction projects where the goal is to strengthen the soil or keep it from shifting. This is done by using heavy machinery to compact the soil tightly together. This method is effective but can be expensive and time-consuming.

Benefits of Compaction:

- The soil will be much stronger and less likely to shift or move.

- Compaction can help to prevent sinkholes from forming.

- It can also help increase the load-bearing capacity of the soil.

Drawbacks of Compaction:

- If not done correctly, compaction can weaken the soil.

- Compaction can also make the soil more difficult to till or dig.

- It is expensive and time-consuming.

Reinforcement:

Reinforcement is often used in construction projects where the goal is to keep the soil from shifting. It is done by placing objects on the ground that will help keep the soil in place. Commonly used reinforcement materials include:

- Plywood

- Tarpaper

- Geotextiles

- Mesh wire

Benefits of Reinforcement:

- It is less expensive than compaction.

- It is used in areas that are difficult to compact.

- You can easily remove it after the project is complete.

Drawbacks of Reinforcement:

- The materials used can be unsightly.

- They can be difficult to remove if the project is not completed as planned.

- They can also be damaged by wind or water.

Drainage:

Another standard method of soil stabilization is drainage. This is done by installing pipes or other drainage systems beneath the ground. This is to remove water from the soil not to become saturated and shift. It will allow water to move through the soil without causing erosion. Drainage can be accomplished through the use of:

- Pipes

- Ditches

- French drains

Benefits of Drainage:

- It can be used in areas that are difficult to drain.

- It prevents water from pooling on the surface of the soil.

- You can use it in conjunction with other methods of soil stabilization.

Drawbacks of Drainage:

- It is not easy to install.

- It may not be effective in all cases.

- It can be expensive.

Conclusion

Soil stabilization is solidifying and strengthening soil to provide a foundation for construction projects. Using suitable materials and methods, you can ensure that your project has a stable base to build.

Bay Country Contractors offers soil stabilization services in Ashburn, VA. We can stabilize any soil, no matter how challenging it may be.

Contact us today for a free estimate, and let us show you what we can do!